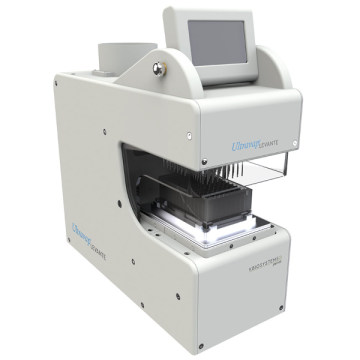

Porvair Ultravap Mistral XT150

The Ultravap Mistral XT150 from Porvair Sciences is a fully automated solvent evaporator specifically designed to accommodate tall tubes up to 150mm in height, making it ideal for high-throughput laboratories handling larger sample formats. Developed in cooperation with leading liquid handling robot manufacturers such as Hamilton, Tecan, PerkinElmer, Beckman Coulter, and Agilent, the Mistral XT150 integrates seamlessly into robotic workflows to enable walkaway automation and streamline sample preparation.

Featuring a sleek, flat-front profile and a motorised plate shuttle, the Mistral XT150 is designed for direct interfacing with robotic arms, allowing effortless plate handling and maximising throughput. It supports up to 15 programmable evaporation methods, each with five ramping stages and precise vertical control in 0.1 mm increments, ensuring efficient and consistent solvent evaporation. The system is compatible with ANSI/SLAS standard microplates and tube holders, now extended to accommodate tubes up to 150mm tall, broadening its application across a wider range of sample types.

Built with safety and scalability in mind, the Mistral XT150 includes integrated obstacle detection, password-protected method control, and an advanced fume management system with ducting capabilities for safe operation. Multiple units can be networked and synchronised via master/slave configurations using CAN bus and RS232 connections to increase throughput further. Compact and user-friendly, with an intuitive touchscreen interface, the Ultravap Mistral XT150 is the perfect solution for laboratories seeking reliable, automated evaporation of larger volume samples in tubes.

All pictures shown are for illustration purpose only. Actual product may vary.

Features

- Part Number – 500292: Ultravap Mistral XT150 Blowdown Evaporator

- Automation-Friendly – Flat front profile and motorised platform shuttle for seamless integration with liquid handling instruments

- Consistent Evaporation – Advanced head technology ensures uniform gas injection up to 80 °C across wells, vials, and tubes

- Clean Concentration System – Designed to minimise risk of cross-contamination between samples

- Sample Protection – Bulk of sample remains at ambient temperature, with only the surface gently heated

- Compact Design – Slim, bench-friendly unit with built-in LED lighting for enhanced sample visibility

- Needle Head Options – Compatible with 12, 24, 48, 96, and 384 needle heads (needle heads available separately)

- Format Compatibility – Supports ANSI/SLAS standard microplates and tube/vial holders and accommodates glass tubes up to 150 mm in height

- Sample Holder Compatibility – Supports holders up to 60 mm high

- Process Control – Ability to pause dry down for increased flexibility