By Tony Taylor

A recent article titled The Robot Report [1] contrasted the performance of robots in industry against those of humans. The article highlighted five areas where robots perform better than humans: Handling tedium, extreme sensing, strength and speed, unwavering focus, and perfect, objective recall. The article also highlighted three areas where humans still outperform robots: empathy, flexibility, acceptability and trust.

By considering these points within the context of a laboratory, we may not take full advantage of the positive aspects of robotics or address the negative aspects. This is especially true when considering sample preparation and sample manipulation.

Most laboratory workers with more than just a few samples to process are familiar with the daily routine of preparing samples, setting up equipment, running a system suitability, checking fitness for purpose, and then starting the “batch” of samples just before leaving work for the evening. Modern instruments have very much reduced the amount of finger crossing required on the journey home and that sense of anticipation upon entering the laboratory the next morning to see if the run worked or not, but those feelings of anxiety have not been eliminated. Automated robotics have the power to change this paradigm, with samples being prepared in a “just-in-time” fashion so that the analysis can begin at the start of the day and much of it will be done as we leave work-preparation and analysis times permitting. We could then even rack up enough samples to do the same thing overnight, improving our throughput if required.

Automated solutions must be robust and reliable, and this is perhaps where the industry needs to evolve, to ensure that our engineering is optimized to the point at which fallibility is not a consideration. Again, most of us are familiar with situations where campaigns have been halted overnight due to a vial not being gripped or picked up properly, or a vial tolerance that has caused the autosampler to reject a particular sample, or even simply to drop the vial. Here evolution in the flexibility and “learning” of the instruments could be improved. Provided that the rejected vial does not lie in a dangerous or obstructive position, the robot should be able to move to the next operation and simply flag the failure in the batch report, provided the sample is not a key System Suitability or QC which may render the remainder of the analyses invalid.

There are myriad situations in which robotics can be used for sample preparation in HPLC and produce a better result than the human laboratory worker. Operations such as sample dilution (including serial dilution), filtration, and derivatization are all possible. There are sample robotics that can handle weighing, mixing, and even centrifugation, yet these solutions aren’t often employed in many HPLC laboratories. Why would that be?

The robot will follow a sample preparation or extraction protocol with much greater precision than a human, provided that it has been properly “trained”. It will also follow the standard operating procedure (SOP) every time. Can we honestly say that we follow the SOP for every sample preparation that we undertake? Always shaking for the precise time, using the same method of agitation, using the same spot in sonic bath, weighing or pipetting using exactly the correct technique – the list goes on! Robots are infallible in terms of recall and repeatability, humans are not.

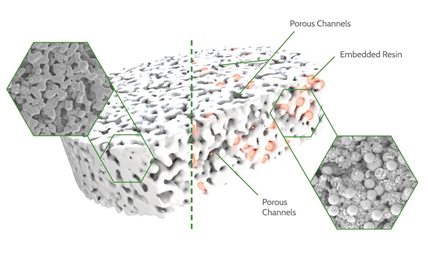

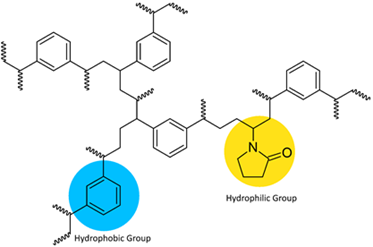

Whilst many sample preparation or extraction protocols in HPLC are relatively straightforward, there are those which are not so simple, such as SPE or more complex liquid–liquid extraction (LLE) protocols. Method development is a time consuming and costly activity, involving the systematic exploration of variables, with the aim of finding the optimum set of conditions for a robust method that yield data of an appropriate quality and cost. In method development, it is vital to vary the parameters under investigation in a stepwise fashion, while automatically, and tightly fixing all other parameters, so that the effect of varying a target parameter isn’t obscured by random variations elsewhere. Manual sample preparation is a significant source of unwanted variation and automating sample preparation, makes method development a more straightforward and predictable process and saves a great deal of time. With more analysts taking a Design of Experiment (DoE) approach to method development, (where several parameters are adjusted simultaneously in a systematic way), automated sample preparation is a logical partner to reduce these unwanted variations. Again, we don’t yet encounter widespread implementation.

Why aren’t robotics commonly used in HPLC

Could it be that we consider sample preparation for HPLC too simple? Not worthy of automation because it can be quickly and easily achieved within the sample preparation laboratory? Ask yourself how many batch failures or laboratory investigations have been related to issues with sample preparation?

Liquid chromatography forms the basis of this discussion, as the gas chromatography (GC) marketplace may be slightly different, more evolved even. There are several manufacturers producing advanced robotics systems for the preparation and manipulation of samples prior to GC analysis and the complexity of the systems is much more advanced than what is allied to HPLC instruments. Furthermore, the systems are fully integrated and can inject the sample into the GC system, with just-in-time sample preparation capabilities. These systems are equipped with many tools that enable weighing, mixing, shaking, heating, centrifugation, solvent evaporation, and a host of other options. This enables operations such as sample dilution, addition of internal standards, derivatization, LLE, solid-phase microextraction (SPME), SPE, and other micro-extraction techniques to be automated.

Even in situations where large sample volumes were traditionally used, such as environmental analysis, automation has been made possible because of advances in mass spectrometric (MS) detection technology and sensitivity, which can be achieved using detectors such as triple quadrupole (QQQ) and quadrupole time-of-flight (QTOF) instruments. Essentially, the increase in detector sensitivity enables much smaller volumes of samples to be processed without compromising limits of detection or quantitation. This reduction in sample volume also means that the automated version of these techniques is not only greener (lower volumes of organic extraction solvents), but achieved within the chromatographic run time, enabling “just-in-time” sample processing for all but the most complex preparation or extraction protocols.

Perhaps this latter point highlights a potential issue with the interfacing of HPLC to robotic auto sampling procedures. With the advent of ultrahigh-pressure liquid chromatography (UHPLC), chromatographic run times are typically very short and lengthy sample preparation protocols would not match the time frame of the separative phase and the overall analysis time may be extended. Here the “batch preparation” robotics with multi-head probes used in bioanalysis (mentioned earlier) may have the edge because the overall campaign time may be reduced. However, when the benefits of improved fidelity, reproducibility, and unattended operation (from fully integrated robotic solutions) are considered, even one sample at a time approaches may still be of considerable benefit in HPLC analysis. Miniaturized sample reparation preparation protocols can be very rapid indeed when using modern automated systems with optimised processing workflows.

What is preventing further implementation of robotic solutions in the GC laboratory? Or the wider scale adoption of robotic approaches in the HPLC laboratory?

The reasons typically cited for low adoption of automation are listed below, specifically regarding sample preparation for chromatography analysis, as well as a short response for each;

Not enough budget for automation?

Did you carry out a Return on Investment (ROI) calculation which included an improvement in right first time a reduction in solvents and the energy to power fume hoods if these are used as part of your current sample preparation routine?

Tried automation before and it didn’t deliver the promised benefits?

Did you work with the manufacturer of the robotic system to fully explore the time/materials and cost savings?

My process couldn’t be automated

I rarely encounter a sample preparation routine which cannot be automated with modern laboratory systems. As I’ve said above, SPE, LLE, weighing, sonication, centrifugation, heating, shaking, dilution, desorption, evaporation, reconstitution and a host of other tasks can be completed using automated systems.

My sample preparation is very straightforward, and I can’t justify the spend to automate something so simple

Did you work with the manufacturer of the robotic system to fully explore the time/materials and cost savings? Did you consider what that analytical chemist or technician could be doing whilst they weren’t doing sample preparation?

Automated approaches can’t meet my sensitivity requirements

This is invariably not the case when the sensitivity of modern mass spectrometry and other detectors are considered, and the workflow optimised to result in a sample of low enough volume to produce a robust detector response.

I don’t trust automation; it adds more complexity and susceptibility

Nothing is more complex or susceptible as a human. The repeatability, accuracy, and relative infallibility of modern robotic systems for sample preparation may be worthy of suspicion for their unerring performance, but I would find it difficult to question their susceptibility.

Automation & Environmental, Sustainability & Governance (ESG)

Perhaps the most important emerging driver for automation, however, is saved until last: that of the controls around Environmental, Sustainability & Governance (ESG). As a society we are becoming ‘greener’ in our mind sets, and whilst we may consider the major business wins in the green agenda to lie outside the laboratory, believe me, these initiatives are coming to a lab near you very soon. The reduction in power, solvent volumes, and exposure of analytical staff to potentially harmful solvents and reagents are clear when using automated platforms. They fit the ESG agenda perfectly and allow us to clearly demonstrate that we take the future of the planet very seriously! There are several Analytical ‘Greenees’ calculators available. A particularly helpful calculator comes from a collaborative group which includes the sample preparation impact of the method and can be found here [2]

Revisiting the title of this piece, do we need to evolve or be left behind? How true is this of automation of sample preparation for chromatographic applications? The flexibility of modern automated systems and the range of tasks they can complete has been vastly improved, even in the past 10 years. Their unfaltering accuracy and repeatability are proven and their ability to reduce worker exposure to both tedium and hazardous reagents or operations can also be clearly demonstrated.

Do we then just fear the “rise of the robots”? Surely not in our modern society. To further investigate the upsides of automation that, you can read the below materials.

Reference

[1] https://www.therobotreport.com/5-things-robots-better-humans/

[2] AGREEprep e Analytical greenness metric for sample preparation. Wojciech Wojnowski, Marek Tobiszewski, Francisco Pena-Pereira, Elefteria Psillakis; Trends in Analytical Chemistry 149 (2022) 116553

Tony Taylor, Chief Scientific Officer, Element Lab Solutions

Tony has worked as a chromatographer in the Pharmaceutical, Polymer, Contract Analysis and Consulting Industries for more than 35 years. His experience includes; HPLC and GC method development, development and troubleshooting of LC-MS and GC-MS methods, HPLC stationary phase characterisation, targeted and untargeted trace analysis, GC-MS spectral interpretation, solid phase extraction and development of sample preparation methods. Tony is a founder of CHROMacademy and has delivered training in chromatographic analysis to thousands of students globally.