As 2024 marks the 50th anniversary of Agilent J&W GC columns, it's a perfect moment to look back on the innovations that have established the standards for today's GC columns. With advancements in selectivity, bleed, inertness, and durability Agilent has consistently pushed the boundaries of GC column technology. Let's delve into the history and look at the evolution of the Agilent J&W GC columns over the past five decades and discover why the history of Agilent J&W is the history of the GC column!

The beginning: the development of the capillary bonded phase

The journey begins in 1974 when Professor Walt Jennings founded J&W Scientific and created the first all-glass capillary bonded phase columns for Gas Chromatography. In 1979, Agilent, then part of Hewlett Packard, invented fused silica capillary tubing. Agilent acquired J&W Scientific in 2000, and in 2010, they acquired Varian Chrompack a company renowned for the introduction of Porouys Layer Open Tubular (PLOT) column technology and a vast array of specialist phases designed for specific industrial applications. Combining and building on the quality and know-how of these three innovative and foundational brands in capillary Gas Chromatography, the Agilent J&W column portfolio has developed into the most comprehensive and well regarded in the market, with over 4,000 column part numbers available under the DB, CP, HP and VF brands.

Image 1: Professor Walt Jennings [1]

Crosslinked and immobilised polysiloxane columns are among the most widely used as they are stable, versatile and robust. They are characterised by the repeating siloxane backbone, with the type and percent level of substitution of the groups distinguishing each stationary phase. The non-polar DB-1 and DB-5 columns are two of the most popular phases offered and are often used as the starting point for new method developments.

J&W WAX columns offer alternative selectivity options compared to standard polysiloxane columns for the analysis of polar analytes. They use a highly polar polyethylene glycol (PEG) polymer stationary phase, and the degree of cross-linking and precise control of the deactivation process result in unique proprietary phase characteristics. The latest innovation in the WAX range is the DB-HeavyWAX column, which features a higher maximum temperature limit. This allows for shorter run times and a wider range of applications compared to standard WAX columns.

As well as the standard polysiloxane and PEG phases, Agilent offers more than 20 speciality phases designed to solve challenging applications in the petroleum, pesticides, PAHs, semi-volatiles, volatiles, foods, flavours and fragrance, and life sciences sectors. In 1986, J&W Scientific introduced DB-624 a mid-polar 6% cyanopropyl/phenyl, 94% polydimethylsiloxane chemistry and the world’s first designer stationary phase. Although it is popular for its use in the USP <467> method for analysing residual solvents in pharmaceuticals, it was originally developed for environmental volatile organic compounds (VOC) analysis under EPA Method 624, hence the name of the phase. Agilent continues to innovate with application specific phases with the recent launch of the DB-FastFAME designed to separate traditional fatty acid methyl esters (FAMEs) in under 8 minutes.

Image 2: Agilent J&W GC capillary columns

PLOT columns deliver separation for compounds that are gases at room temperature

In 1988 the innovation continued with Chrompack, who unveiled the first PLOT (Porous Layer Open Tubular) fused silica capillary columns. These columns excel in separating gaseous compounds at room temperature and have been essential for analysing fixed gases, low molecular weight hydrocarbon isomers, volatile polar compounds, and reactive analytes.

The PLOT column range from Agilent has been developed further for use with GC/MS systems. PLOT PT columns feature integrated particle traps at both ends, ensuring leak-free GC/MS operation. The use of bonded and immobilised stationary phases, such as PoraBOND, GS-GasPro and GS-CarbonPLOT, eliminate the risk of detector fouling caused by particle generation.

Low-Bleed columns designed for MS

In 1991, J&W Scientific introduced the DB-5ms, the first column designed specifically for low-bleed MS applications. This innovation was driven by the increasing use of benchtop GC/MS instruments in analytical labs, requiring highly inert, low-bleed columns for higher-temperature analysis and reduced spectrometric background. Agilent’s special surface deactivation and siloxane chemistries continue to set new standards for column performance to this day.

Agilent's latest launch of the J&W DB-5Q and HP-5Q columns features ultra-low bleed polymers combined with ultra inert surface deactivation to meet the sensitivity and spectrometric requirements of modern tandem and time-of-flight mass spectrometers. The improved column technology increases thermal stability, significantly reducing bleed profiles, leading to more stable baselines and improved accuracy of integration, especially for the most challenging trace-level analytes.

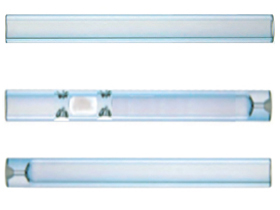

Ultra Inert Technology for consistent inertness performance

The drive for inertness advanced further in 2008 with the introduction of Ultra Inert (UI) GC columns. These columns set new standards for consistent inertness and low column bleed, through the use of specialised chemical deactivation processes. Each UI column undergoes rigorous testing to meet the highest performance standards.

Since then, Agilent has continued to lead the field with the development of UI inlet liners, fittings, ferrules, guard columns, retention gaps, and supplies for inlets and detectors. These supplies ensure an inert flow path, enhancing sensitivity, accuracy, and reproducibility, particularly at trace levels.

Image 3: Agilent Ultra Inert columns and consumables for inert flow path

Design-In GC columns specifically designed for Agilent GC instrumentation

As well as the developments in stationary phase chemistries, Agilent has continued to innovate with the design of GC column hardware to work alongside the latest developments in GC instrumentation. In 2008, Agilent acquired RVM Scientific and introduced LTM (Low Thermal Mass) rapid cycling technology. LTM column modules combine fused silica capillary columns with heating and temperature-sensing components, significantly reducing analytical cycle times and power consumption compared to traditional air-bath GC ovens.

Image 4: LTM column module

The innovation continued with the introduction of the Intuvo GC columns in 2016. These columns, designed for the Intuvo 9000 GC instrument, feature a compact planar design and fast direct heating and cooling technology. The Intuvo system eliminates the need for column trimming and utilises click-and-run connections for easy replacement, further simplifying GC operations.

Image 5: Intuvo GC columns

In 2019, Agilent introduced the Smart Key technology, a device that stores vital information about each GC column, such as age, temperature limits, serial number, and usage. When used with the Agilent 8890 instrument it automates method setup, reduces manual entry errors, and provides maintenance feedback, ensuring optimal column performance and longevity.

Image 6: Agilent GC column with Smart Key

Looking forward to the next 50 years of innovation

Over the past 50 years, Agilent J&W GC columns have revolutionised gas chromatography through continuous innovation and commitment to quality. From the first all-glass capillary bonded phases to today's advanced Ultra Inert and Smart Key technologies, Agilent has set industry standards and consistently provided chromatographers with tools to achieve precise and reliable results. As we celebrate this milestone, and look forward to the future advancements that Agilent will bring to the world of chromatography.